RS & 210 SERIES

Balanced Valve Design

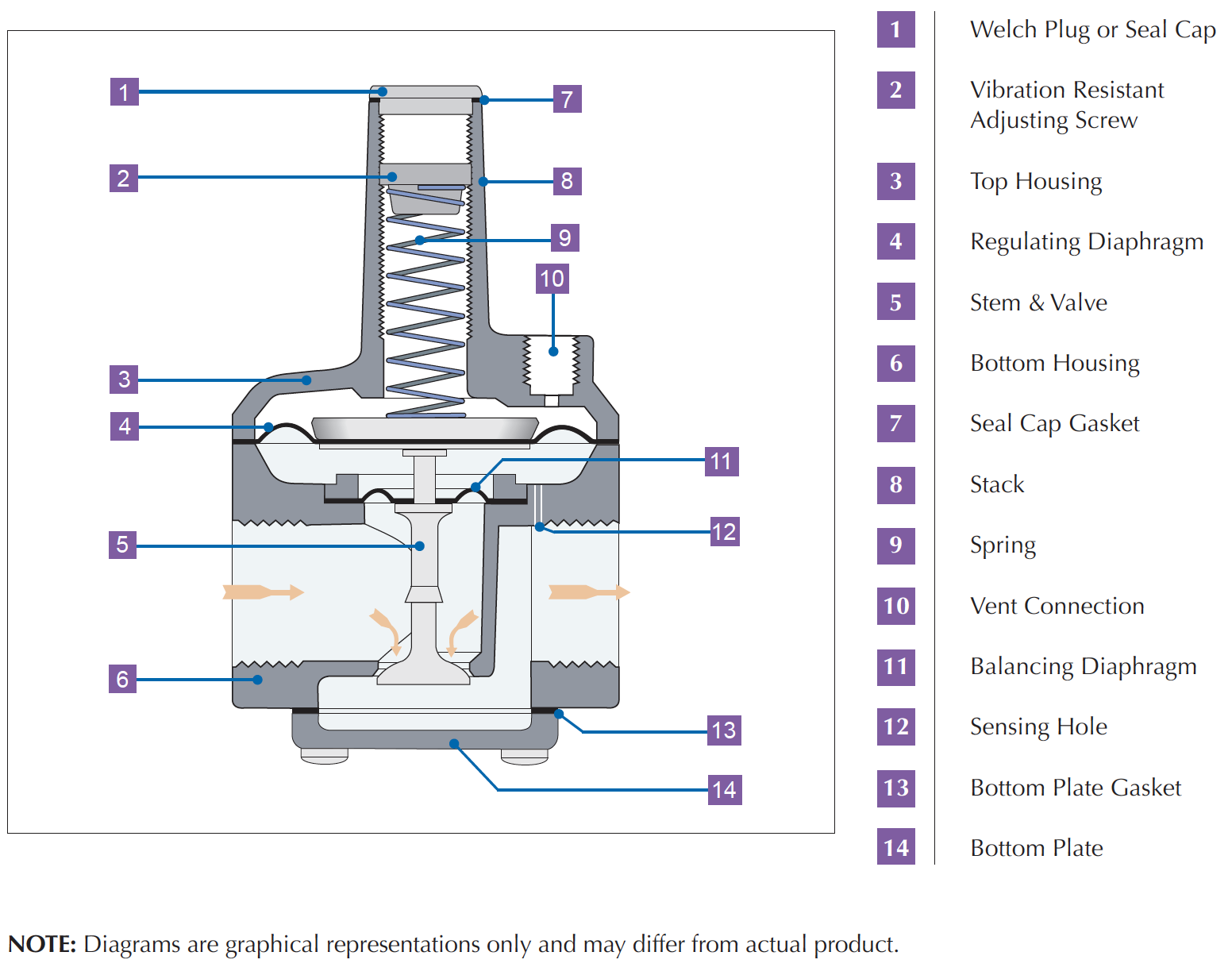

R & RS Series

R & RS Series regulators have a double diaphragm balanced valve design that makes is possible to maintain steady outlet pressure control with widely varying inlet pressures. R & RS series regulators are intended for use with both main burner and pilot load applications. Applications include infrared heaters and pilot lines on large industrial heaters and boilers. They may also be used in residential applications as appliance regulators.

Certifications

![]()

![]()

Fuel Gases

Suitable for natural, manufactured, mixed gases, liquefied petroleum gases, LP gas-air mixtures, and gases of DIN EN 437 gas family 1, 2, and 3

Pipe Sizes

| Model | Pipe Sizes |

| R400(S)… | ⅜”, ½”, Rp ⅜, Rp ½ |

| R500(S)… | ½”, ¾”, Rp ½, Rp ¾ |

| R600(S)… | ¾”, 1″, Rp ¾, Rp 1 |

| R700… | 1″, 1 ¼”, Rp 1, Rp 1 ¼ |

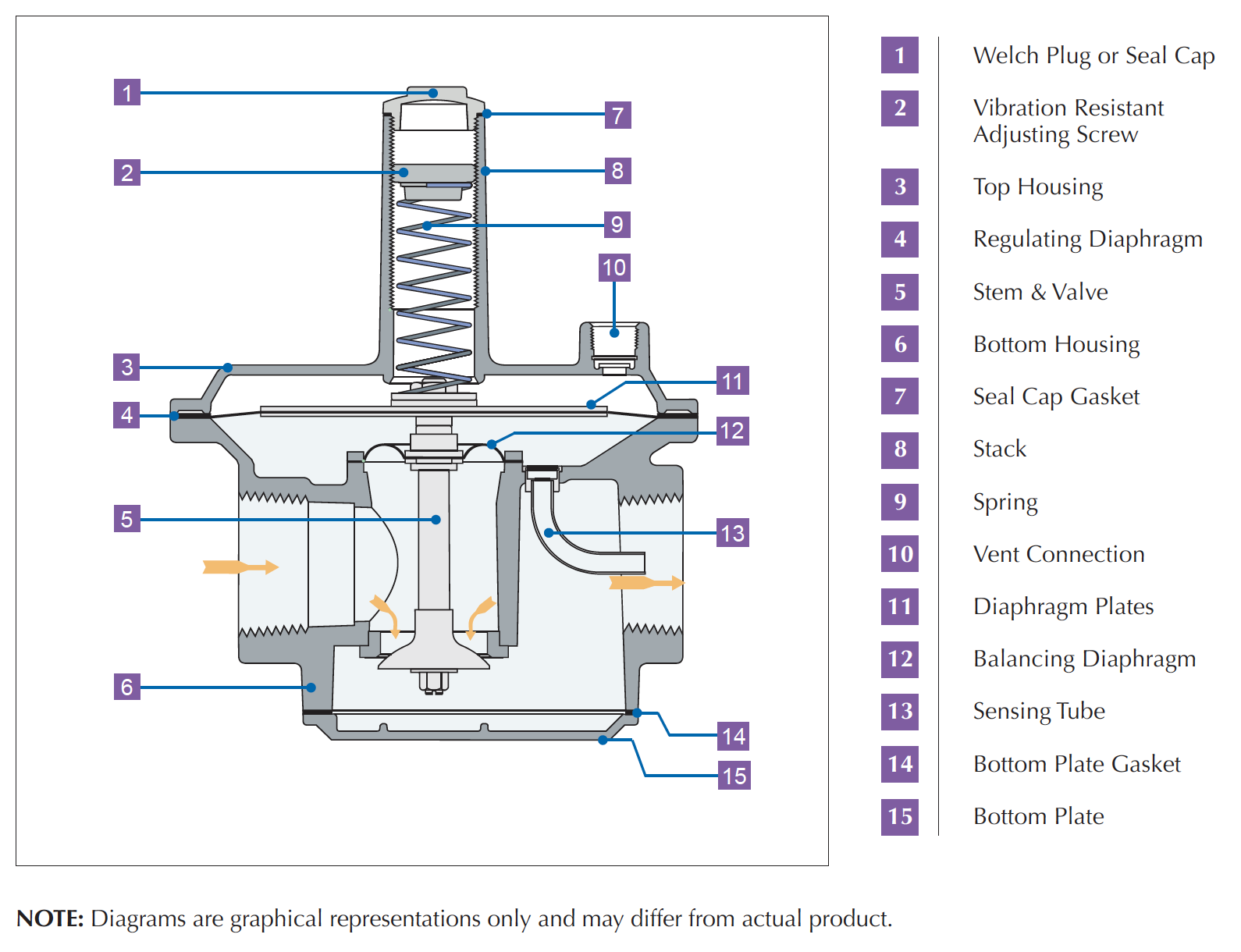

210 Series

210 Series balanced valve design is a lockup-type regulator. The balanced valve design makes it possible to maintain steady outlet pressure control with widely varying inlet pressures. The 210 series provides precise regulation over a wide range of pressures and flow rates. Applications include gas-fired boilers, steam generators, industrial furnaces and ovens. Remote sensing option is available on 210D, E, and G models.

Certifications

![]()

![]()

Fuel Gases

Suitable for natural, manufactured, mixed gases, liquefied petroleum gases, LP gas-air mixtures, and gases of DIN EN 437 gas family 1, 2, and 3

Pipe Sizes

| Model | Pipe Sizes |

| 210D… | 1″, 1 ¼”, 1 ½”, Rp 1, Rp 1 ¼, Rp 1 ½ |

| 210E… | 1 ½”, 2″, Rp 1 ½, Rp 2 |

| 210G… | 2 ½”, 3″, Rp 2 ½, Rp 3 |

| 210J… | 4″, DN100 |

| Title | Description | Version | Download |

|---|---|---|---|

| RS Balanced Valve Design (NA) | Catalog; Lockup type regulator. Maintains steady outlet pressure control with widely varying pressures. (excerpt) | 🇺🇸 North America, Imperial Units; GPR_MS_EN_05.2023 (R/RS) | DownloadPreview |

| 210 Balanced Valve Design (NA) | Catalog; Lockup type regulator. Maintains steady outlet pressure control with widely varying pressures. (excerpt) | 🇺🇸 North America, Imperial Units; GPR_MS_EN_05.2023 (210) | DownloadPreview |

| RS/210 Balanced Valve Design (EU/UK) | Catalog; Lockup type regulator. Maintains steady outlet pressure control with widely varying pressures. (excerpt) | 🇬🇧 EU/UK, Metric Units; GDR.GF-LT-EN_09.2022 (RS/210) | DownloadPreview |

| Gas Pressure Regulator and Modulator Catalog (NA) | Catalog; Gas Pressure Regulators and Modulators (full catalog) | 🇺🇸 North America, Imperial Units; GPR_MS_EN_05.2023 | DownloadPreview |

| Gas Pressure Regulators and Filters Catalog (EU/UK) | Catalog; Gas Pressure Regulators and Filters (full catalog) | 🇬🇧 EU/UK, Metric Units; GDR.GF-LT-EN_09.2022 | DownloadPreview |